In various industries, ensuring the structural integrity and safety of materials is of paramount importance. One crucial aspect of this is measuring material thickness accurately without causing any damage. Non-destructive thickness testing plays a pivotal role in this regard, and high-frequency thickness measurements have emerged as a reliable and efficient method. In this blog post, we will explore different methods of thickness testing, delve into non-destructive thickness testing using ultrasound technology

In pic: measuring pipe thickness using a tape

In pic: an example of a traditional mechanical calipers

Different Methods of Thickness Testing

- Calipers: Traditional mechanical calipers provide a quick and simple way to measure thickness, but they may not be suitable for hard-to-reach or coated surfaces.

- Micrometers: Micrometers offer higher precision than calipers, but they are also limited in their accessibility.

- Eddy Current Testing: This electromagnetic method is ideal for conducting non-destructive thickness tests on conductive materials.

- X-ray Radiography: X-ray radiography can provide valuable insights into material thickness but may involve hazardous radiation exposure.

- Ultrasonic Thickness Testing: Ultrasonic testing uses high-frequency sound waves to measure thickness non-destructively, making it one of the most versatile and widely adopted methods.

Non-Destructive Thickness Testing Using Ultrasound Technology

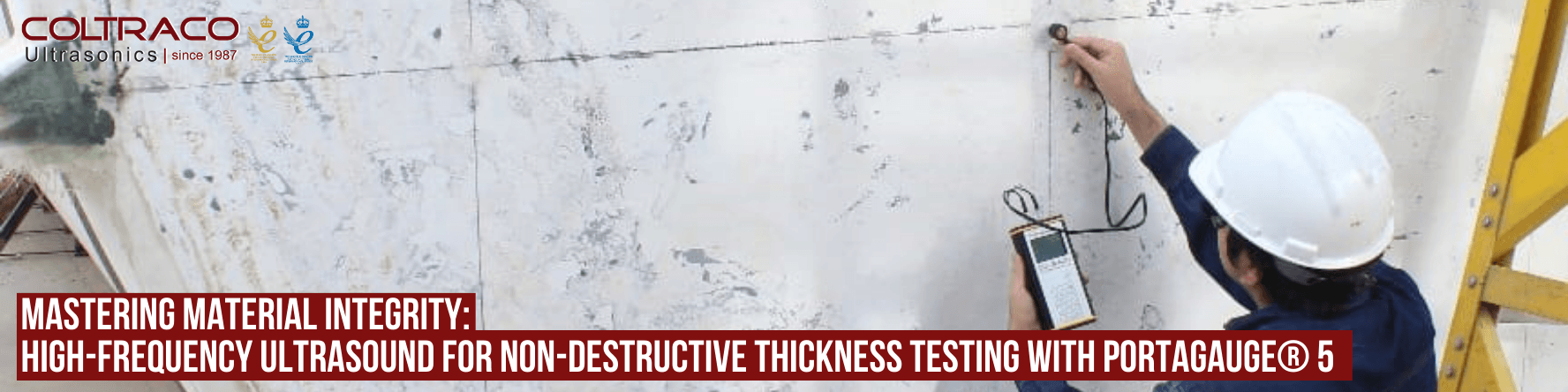

Among the various thickness testing methods, ultrasound technology stands out as a reliable and versatile choice. Coltraco Products’ Portagauge® 5 is a prime example of a multiple echo ultrasonic thickness gauge designed to measure the thickness of metals and hard plastics accurately. It possesses the remarkable ability to ignore paint coatings up to 20mm in thickness, allowing for the measurement of the material’s true thickness.

How Coltraco Products Portagauge® 5 Can Assist

The Portagauge® 5 is specifically engineered to meet the BS EN 15317:2013 standard for ultrasonic testing equipment, ensuring high accuracy and reliability.

Some key advantages of this innovative device include:

- Accurate Readings: Ignores paint coatings up to 20mm thick, providing precise thickness readings accurate to +/- 0.1mm.

- Versatile Units: Measurement units available in both metric (millimeters) and imperial (inches) for user convenience.

- Advanced Functionality: Offers A-scan and oscilloscope trace functionality to assist with measurements and verify the correct return backwall echo.

- Built-in Material Database: Contains speed of sound data for 12+ different materials, with an option to enter custom materials.

- Marine Applications: Meets Classification Society requirements for marine thickness gauge measurement equipment and features an LCD backlight for use in low-visibility spaces.

- Long Battery Life: Operates continuously for up to 12 hours on a standard 9V PP3 battery, with a battery-saving mode.

- Technical Support: Ongoing technical support and advice ensure optimal performance throughout the unit’s lifetime

- Sensor Options: Offers various sensor options to meet specific inspection requirements, including options for measuring thickness on different types of pipes and highly attenuative materials.

Conclusion:

Non-destructive thickness testing using high-frequency ultrasound technology has revolutionized material integrity assessment across multiple industries. Coltraco Products’ Portagauge® 5, with its advanced features and unmatched accuracy, is a testament to the power of innovation in this field. With the ability to ignore paint coatings, a built-in material database, and versatile sensor options, it is an indispensable tool for ensuring the safety and reliability of materials and structures. In an era where precision and non-destructive testing are paramount, Portagauge® 5 sets the standard for excellence in thickness measurement.