Coltraco’s Portamonitor® is a sophisticated AE device that combines Distress® and db levels that provides a real-time evaluation to give the user accurate knowledge of any defects that may be present in any kind of bearing, for example; roller and ball types. Sound generated by friction and impacts caused by poor lubrication or bearing damage propagates as a stress wave, detectable by the Portamonitor®.

Signal is processed at sensor level allowing quick and effective diagnostics. The Portamonitor® can be used for pre-service (proof) testing as well as in-service (re-qualification) testing and condition monitoring.

What are Distress® and db level?

Together Distress® and db level help diagnose defects at sensor level by providing simple alert indications relating to phenomena occurring at the defect location. Generally speaking, Distress® provides an instant indication of the health of the bearings. It measures the transient activity, such as impacts, friction and surface deformation caused by micro-pitting and fractures.

The overall measurement is the summation of abnormal signals generated by defective bearings. Elastic waves that are produced as a result of cracks, fractures or debris produce different frequencies. Algorithms inside the Portamonitor® sort this data for comparison against acceptable limits categorised by a number.

The display on the Portamonitor® will show a numeric value indicating the level of distress, for instance: 5-10 indicates the system in “OK”. Between the value of 10-15 indicates the system is “SUSPECT”, and requires further monitoring, whereas >15 indicates a “POOR” system and requires attention. To help with this understanding, the following chart shows simulated example results and a description of what can be immediately determined:

Looking at this data an operator can determine that gearbox No. 1 and 5 need further investigation, with 5 being the priority since gearbox 1 is SUSPECT, but gearbox 5 is POOR. It may be the case that lubricating a bearing may show a decrease in the Distress® value to an acceptable level thus avoiding a shut-down period. This can be determined at this point.

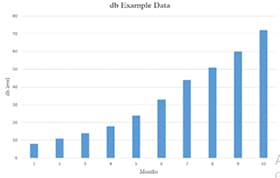

In use alongside Distress®, db level indicators are used which show the overall bearing noise. This is dependent on rotating speed and will increase as rotating speeds increases, but will also increase during the degradation of bearings, or if inadequate lubrication is present. Decibel indicators work on a logarithmic scale, which basically translates very large or very small numbers into a more intuitive form, usually between 0 – 100. Sharp increases in db level indicate imminent failure. Also, db trends can be monitored to establish the overall condition of bearings. Again, to show this we look at some example data to the right.

The trend of db level with time is particularly useful for indicating the rate of deterioration. As can be seen on this chart. This increase in db level over time indicates a serious problem prevailing. Most of the complicated post-processing has been completed within the device making it very easy to understand. Both of these parameters are included simultaneously on the Portamonitor® providing a time and cost effective all-around simple to use device suitable for the monitoring of bearing degradation in all industries.