In hazardous environments like ATEX Zone 1 areas where the risk of fire and explosion is ever-present, ensuring the readiness of fire suppression systems is paramount. Fire suppression cylinders, containing agents vital for extinguishing fires, must be maintained at optimal levels to swiftly combat any potential blaze. However, traditional methods of manually checking liquid levels in these cylinders can be inefficient, risky, and prone to human error. Enter ultrasonic liquid level indicators – advanced technology offering numerous benefits in safeguarding against fire emergencies in hazardous settings.

Precise and Accurate Measurements

Ultrasonic liquid level indicators provide precise and accurate measurements of the contents within fire suppression cylinders without the need for direct contact.

- Utilizes ultrasonic waves to determine the liquid level

- Eliminating the risk of contamination

- Ensures the integrity of the fire suppression agent remains intact.

In ATEX Zone 1 environments where even minor errors can lead to catastrophic consequences, the reliability of ultrasonic technology is invaluable.

Safety and Compliance

Safety regulations in hazardous environments demand rigorous adherence to standards to mitigate the risks associated with fire and explosion. Ultrasonic liquid level indicators offer a safe and compliant solution for monitoring fire suppression cylinders, enabling personnel to conduct inspections without exposing themselves to potentially hazardous substances. By ensuring compliance with regulatory requirements, businesses operating in ATEX Zone 1 environments can enhance workplace safety and minimize the likelihood of accidents.

Quick and Easy Testing with Portable Units

One of the significant advantages of ultrasonic liquid level indicators is how quick and easy it is to test with a portable unit that allows early detection, such as the onset of any leaks. By simplifying the testing process and providing instant feedback, these portable units facilitate proactive maintenance and minimize the risk of cylinder depletion during critical moments. This proactive approach ensures that fire suppression systems remain fully operational when needed most, enhancing overall safety and readiness.

Cost-Efficiency and Operational Efficiency

Investing in ultrasonic liquid level indicators can lead to long-term cost savings and operational efficiencies for businesses operating in hazardous environments. By automating the monitoring process and reducing the need for manual inspections, these advanced technologies streamline maintenance workflows and optimize resource allocation. Moreover, by preventing the premature discharge of fire suppression agents due to inadequate levels, organizations can avoid costly downtime and potential damage to property and personnel.

Versatility and Adaptability

Ultrasonic liquid level indicators are highly versatile and adaptable to various types of fire suppression cylinders and environments. Whether installed in CO2 cylinders, foam extinguisher tanks, or other types of fire suppression systems, these devices offer consistent and reliable performance across different applications. Their flexibility allows businesses to implement standardized monitoring solutions tailored to their specific needs, ensuring comprehensive coverage and protection against fire hazards.

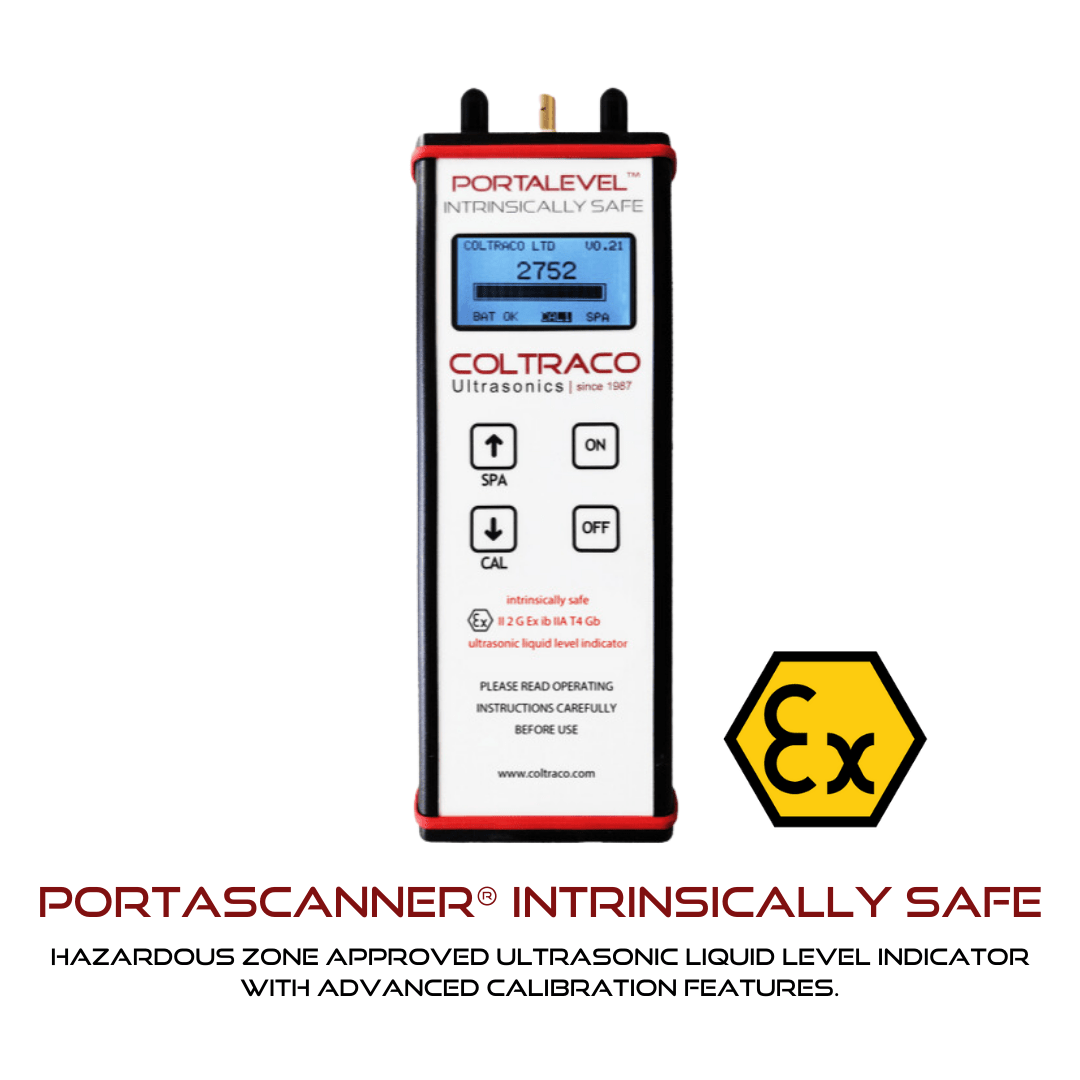

Choose the Portalevel® Intrinsically Safe

In hazardous environments such as ATEX Zone 1 areas, where the consequences of fire emergencies can be severe, leveraging advanced technologies like ultrasonic liquid level indicators is essential for maintaining safety and compliance. By providing precise measurements, enhancing operational efficiency, and enabling quick and easy testing with portable units, these innovative solutions offer invaluable support in safeguarding against fire incidents and protecting lives and assets. Investing in ultrasonic liquid level indicators represents a proactive approach to fire safety, empowering organizations to mitigate risks and ensure readiness in the face of potential threats.

Coltraco’s Portalevel® Intrinsically Safe device stands out as the device of choice for ultrasonic liquid level monitoring in such demanding settings. Built to the highest safety standards, this portable unit is certified as intrinsically safe, meaning it is designed to prevent the ignition of hazardous atmospheres. Its robust construction and advanced technology enable reliable and accurate measurements of fire suppression cylinder contents without compromising safety. With its user-friendly interface and portability, the Portalevel® Intrinsically Safe device offers unparalleled ease of use, allowing personnel to conduct inspections with confidence and efficiency in hazardous environments. By choosing Coltraco’s Portalevel® Intrinsically Safe device, businesses can enhance their fire safety protocols and ensure compliance with stringent regulatory requirements while minimizing risks to personnel and assets.

Learn more about our Portalevel® Intrinsically Safe