The effective testing of Fire Doors for Air Permeability Values is needed, to inhibit the infiltration of smoke and toxic gases and which accurately indicate the amount of air that would flow through Fire Door gaps by measuring the amount of air leakage rate per hour, per square metre of building envelope area at a test reference pressure differential across the building envelope of 50 Pascal (50 N/m2) .

Functioning Fire Doors are very effective at retaining fire for a period, and cold smoke seals fill their weak point, which is the space between the door and the frame, to ensure an airtight seal. Fire, and the toxic products of combustion will travel through any sized gap or crack to the air beyond, and it is vital that all Fire Doors always close correctly to form an airtight seal.

When the lethal products of combustion start to spread in a building, leakages can occur through clearances between the door leaf and the frame, and through any sized gap or crack. Inhalation of smoke, toxic gases and of toxic particulate matter is lethal.

We have over 20 years’ experience in the Fire Safety sector and recognise that advanced technological solutions have customarily been resisted by it. Since our unique airtight technology is the result, in so many ways, of the Government’s determination to identify new technologies to prevent COVID19 during the pandemic, and is globally considered to be state-of-the-art, because it can identify and quantify a leak site, calculate its airflow, and generate its Air Permeability Value, it is an immediate practical solution to check the airtightness of Fire Doors, in relation to their performance that considers the whole building in which they are installed, rather than in isolation from the building.

As part of the Government’s Emergency Response to the COVID19 pandemic, Coltraco Ultrasonics were grateful to win an Innovate UK award in 2020 to conduct research on one of our existing maritime technologies (to prevent ships from sinking at sea by checking that its seals were watertight), and to explore whether this technology could be adapted for use within NHS hospitals to prevent infection spread of airborne diseases. We succeeded in record time, our research was independently assessed as “outstanding”, and we successfully developed the Portascanner™ COVID19, a simple tablet-based instrument to detect, locate and quantify air leaks from negatively pressurised NHS ICU Wards, to prevent infection spreading from them to the rest of the Hospital.

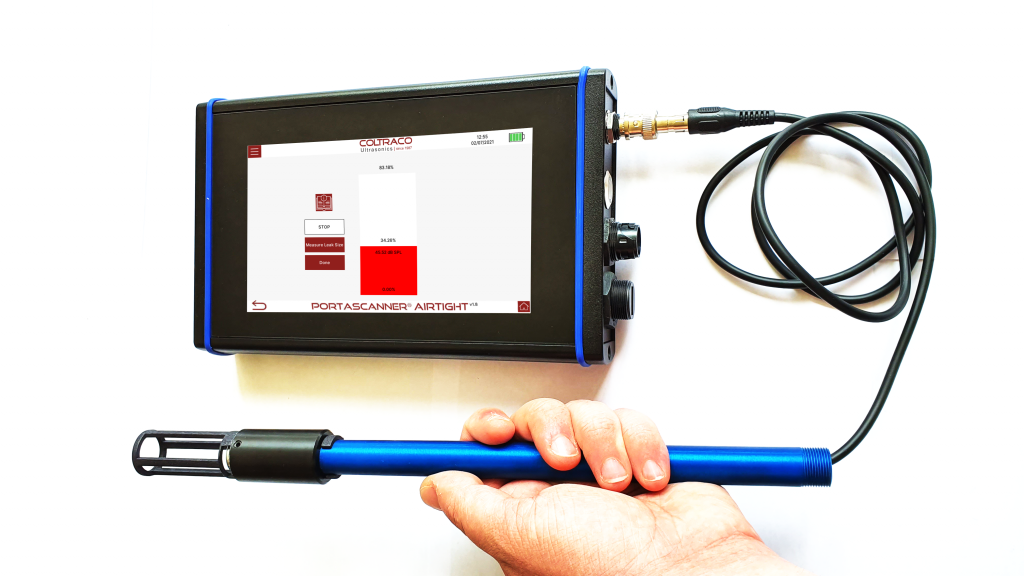

Smoke and toxic gases, which frequently and tragically account for the majority of deaths in a fire in a building, have similar-sized particles as infectious virus particles, and follow similar air paths. This connects our previous work with the development of the Portascanner™ COVID19, to our subsequent “at risk” development of Portascanner™ AIRTIGHT, a micro air-leak detector, with applications throughout the Built Environment, where airtight seals are required to allow for the ventilation of pathogen-free air to enable “safe working” in Commercial Buildings.

Portascanner™ AIRTIGHT is a fast, accurate and simple method of testing room and building integrity, often referred to as compartmentation, related to fire-stopping in doors, walls, ceilings, and floors, to prevent the spread of fire, smoke, and toxic gases. This micro-air leak instrument provides an interpretation of the fire resistance of the desired locations by identifying and quantifying the overall leakage of a room or compartment within a building and generating the Air Permeability Value.

Portascanner™ AIRTIGHT provides verification of room and building integrity, well beyond the current rudimentary visual and mechanical inspections as to how airtight that closure might be, empowering Fire Safety personnel to generate and export accurate digital reports, to ensure that Responsible Persons are fully compliant with legislation coming into force in England and Wales on 23 January 2023. The quantification of air flow rates is one of the most innovative aspects of the Portascanner™ AIRTIGHT, as no other commercially available device has the capability of quantifying air flow rates from individual leak sites, and recording this, so that it can be digitally stored, and shared.