Flow measurement is a critical aspect of various industrial processes, ensuring the efficient movement of fluids through pipelines and systems. Precise metering of water flow is essential for optimizing processes, monitoring water meters consumption, and maintaining operational efficiency. Among the array of technologies available for flow measurement, ultrasonic technology, also known as ultrasonik, has emerged as a versatile and reliable solution, finding applications in a wide range of industries.

In pic: Pipeline inside the Oil & Gas Industry.

In pic: An existing piping system at a Power Generation industry.

Industries Requiring Flow Measurement

Flow meter for measuring fluid flow rate plays a pivotal role in numerous industries, each with unique requirements. Some of the key industries that heavily rely on accurate flow measurement transmitters include:

- Oil and Gas: In the oil and gas industry, precise clamp-on meter flow measurement is crucial for determining production rates, monitoring pipeline integrity using non-destructive testing (NDT), and ensuring the accurate allocation of resources.

- Water and Wastewater: Municipal water treatment plants and wastewater facilities utilize ultrasonic sensors for flow measurement to manage the distribution of clean water and the treatment of wastewater.

- Chemical Processing: Flow metering water is integral to chemical manufacturing, helping control the mixing of various components, optimizing reactions, and maintaining product consistency.

- Power Generation: Thermal and nuclear power plants use ultrasonic flow meters to monitor coolant flows, steam production, and overall energy efficiency.

- Food and Beverage: In food processing and beverage production, accurate ultrasonic flow measurement ensures precise ingredient mixing, packaging, and distribution.

- Pharmaceuticals: Flow meters ultrasonic technology is vital for maintaining quality and consistency in pharmaceutical manufacturing processes, such as blending, filling, and packaging.

- Mining and Minerals: Ultrasonic flow measurement aids in managing slurry flows, chemical dosing, and various mineral processing operations.

- Agriculture and Irrigation: Flow meter for fluid flow rate measurement helps optimize irrigation systems, manage water usage, and ensure proper distribution across agricultural fields.

Ultrasonic Flow Measurement Sensors

Ultrasonic flow measurement technology has gained prominence due to its non-invasive nature and versatility. It operates on the principle of transmitting ultrasonic pulses through a fluid and measuring the time taken for the pulses to travel between two points. This time difference is used to calculate the flow velocity, which, when combined with the pipe’s cross-sectional area, gives the flow rate. Ultrasonic sensors and ultrasonic testing play a crucial role in this process.

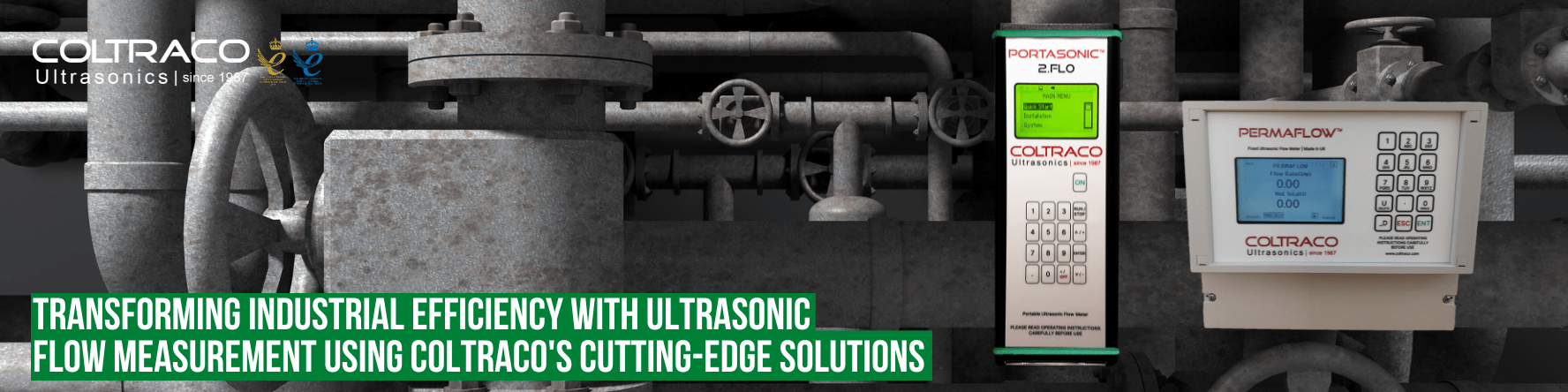

Coltraco Products: Portasonic® 2.FL0 and Permaflow®

Coltraco, a leader in ultrasonic technology solutions, offers innovative products that excel in flow metering applications. The Portasonic® 2.FL0 and Permaflow® are two prime examples.

The Portasonic® 2.FL0 is a cutting-edge ultrasonic flow meter that offers high accuracy, versatility, and a user-friendly interface. Its remarkable features include:

Key features of the Portasonic® 2.FL0:

- Unparalleled Accuracy: Boasting a precision of +/- 0.5%, the Portasonic® 2.FL0 ensures consistently reliable flow rate measurements using ultrasonic sensors.

- Versatile Compatibility: Designed for pipes ranging from DN15 to DN2500 and adaptable to various pipe materials, it suits a multitude of industries and applications, including gas flow metering.

- Comprehensive Measurements: This device excels in measuring volumetric flow rate, mass flow rate, and heat/energy flow rate, providing a holistic understanding of fluid behavior.

- Integrated Oscilloscope: The built-in oscilloscope aids in signal diagnostics during setup, enhancing measurement accuracy and efficiency.

- Ultrasonic Thickness Gauge: The integrated ultrasonic thickness gauge facilitates non-destructive testing and pipe wall thickness measurement, essential for maintenance decisions.

- User-Friendly and Portable: Its handheld structure, intuitive interface, and digital display contribute to efficient operation, while extended battery life minimizes downtime.

The Permaflow® stands out with its modular design, temperature monitoring capabilities, and seamless integration into existing control systems. Notable advantages include:

Key features of the Permaflow®:

- Exceptional Accuracy: With a deviation of only +/- 0.5%, Permaflow® sets a high standard for precise and dependable measurements using ultrasonic sensors.

- Versatile Measurement Units: Supporting volumetric flow rate, mass flow rate, and heat/energy flow rate measurements, it adapts to diverse application needs, including vortex flow meter monitoring.

- Temperature Monitoring: Equipped with PT100 thermometer inputs, Permaflow® enables simultaneous temperature monitoring, optimizing heating or cooling calculations.

- Modular Design and Expandability: Permaflow® features a modular layout with customizable I/O modules, allowing tailored configurations while minimizing costs and resource usage.

- Seamless Integration: By integrating seamlessly with existing control systems via communication protocols like USB, RS232, Modbus, Profibus, and Ethernet, it facilitates smooth data transfer and cooperation with other monitoring and control devices.

Conclusion:

Flow measurement is a vital aspect of industrial processes, and ultrasonic technology has proven to be a reliable and versatile solution. Coltraco’s Portasonic® 2.FL0 and Permaflow® exemplify the advancements in ultrasonic flow measurement, offering exceptional accuracy, comprehensive measurement capabilities, and seamless integration into various industries. As technology continues to evolve, including doppler ultrasonic flow meters and transit time flow meters, these innovations pave the way for more efficient and optimized industrial operations.