Flow measurement is a critical aspect of various industries, from oil and gas to chemical processing and water management. Accurate flow measurements are essential for optimizing processes, ensuring safety, and minimizing waste. Traditional methods of flow measurement often involve invasive techniques that can disrupt the fluid flow and pose safety hazards. In recent years, non-invasive flow measurement technologies have seen significant advancements, leading to improved accuracy and efficiency.

Different Types of Flow Measurements:

- Ultrasonic Flow Measurement: Ultrasonic flow measurement utilizes high-frequency sound waves to measure the velocity of a fluid within a pipe. The time it takes for sound waves to travel upstream and downstream in the fluid is used to calculate the flow rate.

- Doppler Flow Measurement: Doppler flow measurement relies on the Doppler effect, where sound waves reflect off particles or bubbles in the fluid. Changes in the frequency of reflected waves are used to determine flow velocity.

- Magnetic Flow Measurement: In this method, a magnetic field is applied to the fluid, and electrodes on the pipe’s inner surface measure the voltage generated by the movement of charged particles in the fluid. This voltage is proportional to the flow rate.

The Importance of Accurate Flow Measurement:

Accurate flow measurement is crucial for several reasons::

- Process Optimization: Accurate flow measurements help industries optimize their processes, leading to increased efficiency and reduced operating costs.

- Safety: In industries where fluid flow plays a critical role, such as oil and gas, accurate flow measurements are essential for ensuring the safety of equipment and personnel.

- Environmental Impact: Accurate flow measurements enable better control over resource usage and can help reduce environmental impact by minimizing waste.

Non-invasive Ultrasonic Testing of Flow Measurements:

Ultrasonic flow measurement, utilizing high-frequency sound waves, offers precise, versatile, and non-invasive data collection with integrated diagnostic tools, promoting safety, efficiency, and resource conservation across industries.

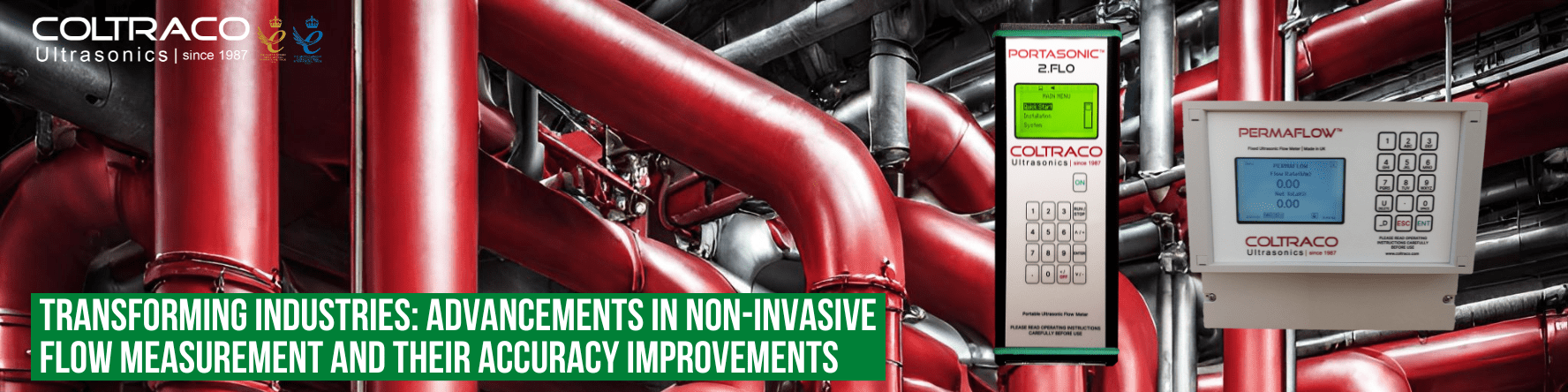

One of the most significant advancements in non-invasive flow measurement is the use of ultrasonic technology. Ultrasonic flow meters, such as the Portasonic® 2.FL0 and Permaflow® from Coltraco Products, offer unparalleled accuracy and versatility.

Portasonic® 2.FL0: This cutting-edge ultrasonic flow meter provides high accuracy, versatility, and a user-friendly interface. Key advantagesinclude:

- Unparalleled Accuracy: Boasting a precision of +/- 0.5%, the Portasonic® 2.FL0 ensures consistently reliable flow rate measurements using ultrasonic sensors.

- Versatile Compatibility: Designed for pipes ranging from DN15 to DN2500 and adaptable to various pipe materials, it suits a multitude of industries and applications, including gas flow metering.

- Comprehensive Measurements: This device excels in measuring volumetric flow rate, mass flow rate, and heat/energy flow rate, providing a holistic understanding of fluid behavior.

- Integrated Oscilloscope: The built-in oscilloscope aids in signal diagnostics during setup, enhancing measurement accuracy and efficiency.

- Ultrasonic Thickness Gauge: The integrated ultrasonic thickness gauge facilitates non-destructive testing and pipe wall thickness measurement, essential for maintenance decisions.

- User-Friendly and Portable: Its handheld structure, intuitive interface, and digital display contribute to efficient operation, while extended battery life minimizes downtime.

Permaflow®: This modular ultrasonic flow meter is known for its exceptional accuracy, temperature monitoring capabilities, and seamless integration into existing control systems. Key advantages include:

- Exceptional Accuracy: With a deviation of only +/- 0.5%, Permaflow® sets a high standard for precise and dependable measurements using ultrasonic sensors.

- Versatile Measurement Units: Supporting volumetric flow rate, mass flow rate, and heat/energy flow rate measurements, it adapts to diverse application needs, including vortex flow meter monitoring.

- Temperature Monitoring: Equipped with PT100 thermometer inputs, Permaflow® enables simultaneous temperature monitoring, optimizing heating or cooling calculations.

- Modular Design and Expandability: Permaflow® features a modular layout with customizable I/O modules, allowing tailored configurations while minimizing costs and resource usage.

- Seamless Integration: By integrating seamlessly with existing control systems via communication protocols like USB, RS232, Modbus, Profibus, and Ethernet, it facilitates smooth data transfer and cooperation with other monitoring and control devices.

Conclusion:

Advancements in non-invasive flow measurement technologies, particularly ultrasonic flow meters like the Portasonic® 2.FL0 and Permaflow®, have revolutionized flow measurement accuracy. These devices offer high precision, versatile compatibility, and user-friendly interfaces, making them indispensable tools for industries that rely on accurate flow measurements. The integration of ultrasonic technology in these devices ensures that flow measurements can be conducted without compromising the integrity of the fluid flow, resulting in safer, more efficient, and environmentally conscious operations.