Ultrasonic flow meters are commonly used in various industrial applications to measure the flow rate of liquids and gases. There are two main types of ultrasonic flow meters: transit time and Doppler flow meters. This article will examine these two types of ultrasonic flow meters, their working principles, advantages, and limitations.

What are Transit Time Flow Meters?

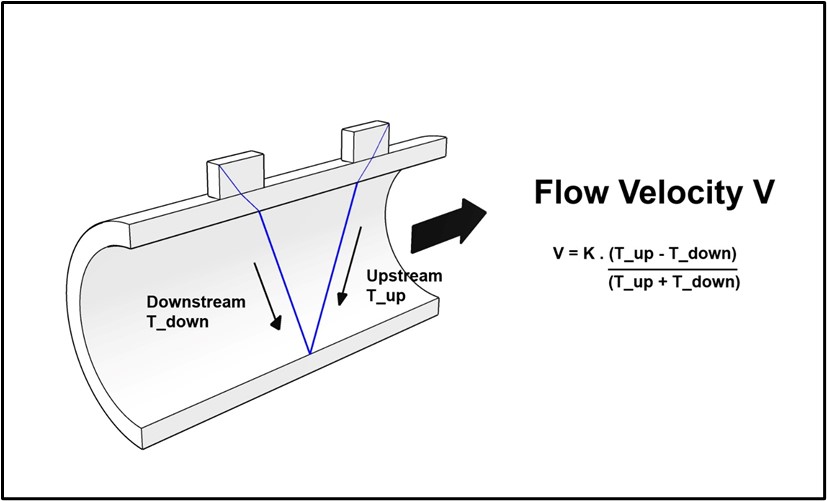

Transit time flow meters measure the time difference between upstream and downstream ultrasonic signals to determine the velocity of the fluid. This type of flow meter works on the time-of-flight principle, where an ultrasonic signal is transmitted through the liquid and received by a downstream receiver.

The transit time of the ultrasonic signal is affected by the velocity of the fluid. When the liquid flows in the same direction as the ultrasonic signal, the transit time is shorter, while it is longer when the fluid is flowing in the opposite direction. By comparing the transit times of upstream and downstream signals, the flow meter calculates the velocity of the liquid.

One of the significant advantages of transit time flow meters is that they can measure the flow rate of both liquids and gases.

They are also relatively inexpensive and easy to install, making them popular for many industrial applications. However, they may not be suitable for fluids that contain bubbles or solids, as they can affect the accuracy of the measurements.

What are the Types of Transit Time Flow Meters?

Transit time flow meters can be further classified into single-path and dual-path.

Single-path transit time flow meters have a single transducer that alternates between transmitting and receiving signals. They are suitable for measuring the flow rate of clean liquids that do not contain bubbles or solids. However, their accuracy may be affected by fluid properties such as temperature, pressure, and viscosity.

Dual-path transit time flow meters have two transducers opposite each other. One transducer transmits an ultrasonic signal while the other receives it. They are more accurate than single-path flow meters and can compensate for changes in fluid properties. They are also suitable for measuring the flow rate of liquids that contain bubbles or solids.

Transit time flow meters are commonly used in industries such as water and wastewater treatment, chemical processing, and oil and gas. They are suitable for measuring the flow rate of fluids with low to medium viscosity.

What are Doppler Flow Meters?

Doppler flow meters work on a different principle than transit time flow meters. They use the Doppler effect to measure the velocity of the fluid. The Doppler effect refers to the change in frequency of a wave when the source and the receiver are moving relative to each other.

In Doppler flow meters, an ultrasonic signal is transmitted into the fluid at an angle. When the signal encounters moving particles or bubbles in the liquid, its frequency changes, creating a shift in the signal frequency. The flow meter calculates the fluid’s velocity by measuring the signal’s frequency shift.

Doppler flow meters are well-suited for fluids that contain bubbles or solids since they rely on the movement of these particles to measure the velocity of the fluid. However, they may not be as accurate as transit time flow meters when measuring the flow rate of liquids, and they require a certain degree of particle concentration to function correctly.

What are the Types of Doppler Flow Meters?

Doppler flow meters can also be further classified into fixed-angle and variable-angle.

Fixed-angle Doppler flow meters have a fixed angle between the ultrasonic signal and the direction of the fluid flow. They are suitable for measuring the flow rate of fluids with high particle concentrations.

Variable-angle Doppler flow meters have an adjustable angle between the ultrasonic signal and the direction of the fluid flow. They can be used for liquids with lower particle concentrations and are more versatile than fixed-angle flow meters.

Doppler flow meters are commonly used in mining, pulp and paper, and wastewater treatment industries. They are suitable for measuring fluid flow rate that contains bubbles or solids.

What are the Advantages and Limitations

Transit time flow meters have the advantage of measuring the flow rate of both liquids and gases. They are also relatively inexpensive and easy to install. However, they may not be suitable for fluids that contain bubbles or solids, as they can affect the accuracy of the measurements.

Doppler flow meters are well-suited for fluids that contain bubbles or solids since they rely on the movement of these particles to measure the velocity of the fluid. However, they may not be as accurate as transit time flow meters when measuring the flow rate of liquids. They also require a certain degree of particle concentration to function correctly.

In conclusion, ultrasonic flow meters are valuable tools for measuring the flow rate of liquids and gases in industrial applications. The two main types of ultrasonic flow meters are transit time and Doppler flow meters. Transit time flow meters measure the time difference between upstream and downstream signals, while Doppler flow meters use the Doppler effect to measure the velocity of the fluid. Both flow meter types have advantages and limitations, and their choice depends on the application’s specific needs.

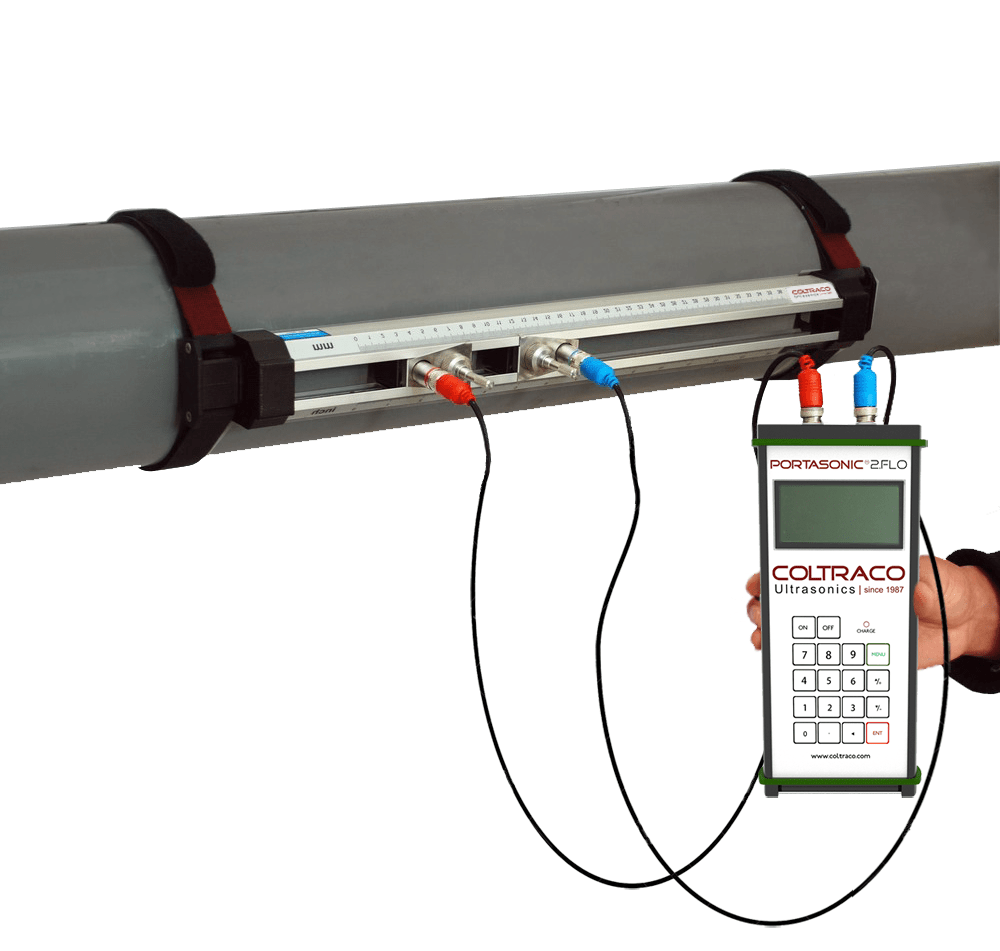

For More Advice & Guidance on the Best Ultrasonic Flow Meter, Contact Coltraco Today

The purpose of leak testing is a vital part of the procedure when it comes to checking and maintaining a ship’s hatch cover. Accurate and reliable testing can help verify that the hatch cover is sealed correctly, giving much-needed peace of mind to vessel owners and operators.

From simple hand checks to more sophisticated methods such as tracer gas testing and water test flooding, all forms have advantages and disadvantages, making it essential to select the most appropriate way depending on the requirements. If you need further information or advice on leak testing or ultrasonic-level measurement solutions for ship’s hatches, contact Coltraco Ultrasonics today.

With decades of industry experience in designing world-leading products for the marine sector, Coltraco has got you covered.