At Coltraco Ultrasonics, we help you measure flow rates with precision, efficiency, and zero disruption.

Our non-invasive ultrasonic flow measurement systems allow you to monitor liquids and gases in real time, helping you reduce waste, ensure process control, and meet regulatory requirements across multiple industries.

Whether you’re managing flow in a treatment facility, a manufacturing line, or a large-scale energy system, we provide the tools and insights to help you operate smarter and more sustainably.

Importance of measuring flow rates and its inherent challenges

Why Is Flow Rate Measurement So Important?

Flow rate measurement is essential wherever fluids, liquids or gases move through pipelines, systems, or processes. The ability to monitor flow accurately ensures that the right amount of material is delivered at the right time, supporting quality control, safety, and operational efficiency.

Flow rate data helps reduce downtime, minimise product waste, and ensure your systems meet environmental or safety regulations.

From pharmaceutical manufacturing to power generation, having access to accurate, real-time flow measurements helps you make informed decisions, respond to faults faster, and improve long-term performance.

What Is Flow Rate Measured In?

Flow rate is measured in volumetric or mass units depending on the application. Volumetric flow refers to the amount of space a fluid occupies as it passes through a point in a system over time. Standard units include litres per second (L/s), gallons per minute (GPM), or cubic metres per hour (m³/h).

Mass flow considers the fluid’s weight over time, often measured in kilograms per second (kg/s) or pounds per hour (lb/h).

For gas systems, measurements such as standard cubic feet per minute (SCFM) or cubic metres per second (m³/s) reflect varying pressure and temperature conditions.

Understanding the difference between volumetric and mass flow, and when each applies, is critical to choosing the proper flow rate monitoring equipment. Each industry will have its preferred units, often driven by legal standards, process design, or fluid characteristics.

What Makes Flow Rate Measurement So Challenging?

Flow rate measurement is not as straightforward. Several variables can impact the accuracy and reliability of results, and overcoming these challenges is key to maintaining consistent operations.

Fluid properties play a significant role. Viscosity, density, temperature, and flow regime all affect how a fluid behaves. Highly viscous liquids may slow down or generate pressure drops. Low-viscosity fluids, especially gases, may result in turbulent flow, which affects measurement stability.

The design and condition of the pipe system also matter. Bends, valves, and fittings can disrupt the flow profile, leading to non-uniform velocities across the pipe diameter. If the flow is not uniform, results can be skewed unless the measurement method accounts for this.

Environmental conditions such as vibration, temperature fluctuations, or electromagnetic interference can disrupt sensitive equipment, especially in industrial environments. A robust, reliable, and noninvasive flow rate monitoring system is essential.

Improper installation is another common issue. When meters are installed too close to obstructions or without adequate straight lengths of pipe, it affects the accuracy of readings. Calibration errors and lack of maintenance further degrade performance over time.

To address these issues, Coltraco provides ultrasonic flow meters that avoid many of the pitfalls of traditional inline measurement.

Using a non-invasive, clamp-on approach reduces setup complexity while ensuring you still receive high-accuracy readings under real-world conditions.

How Do Our Ultrasonic Flow Rate Measurement Devices Work?

Our ultrasonic flow measurement systems use transit-time technology to calculate how long an ultrasonic pulse takes to travel with and against a fluid’s flow. The difference between these times is used to determine flow rate accurately and without interfering with the pipe or fluid.

This method allows measurement without cutting into the pipe, stopping the process, or introducing contamination risk. It’s ideal for both temporary testing and long-term monitoring.

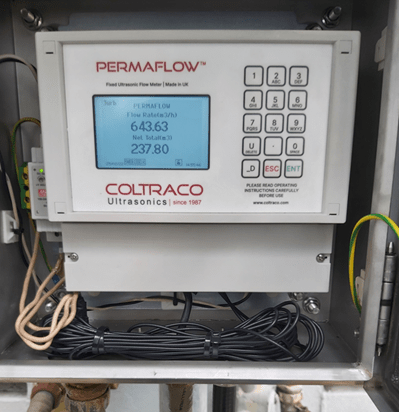

The Permaflow® is our fixed-installation ultrasonic flow meter. It offers continuous real-time monitoring, measures volumetric and mass flow, and operates across various pipe sizes, materials, and liquid types. It provides accuracy within ±0.5% under ideal conditions and supports multiple output protocols, including 4–20 mA, MODBUS, and PT100 temperature inputs.

For mobile or field applications, the Portasonic® 2.FL0 offers portable, battery-powered ultrasonic flow rate measurement.

It’s used widely for spot checks, maintenance, and troubleshooting when fixed monitoring isn’t practical.

Both devices help you gain insight into system performance without introducing the complications of invasive equipment.

Where Can You Use Flow Rate Monitoring?

Flow rate monitoring is essential across a wide range of sectors. In industrial manufacturing, precise flow rate monitoring ensures correct dosing of chemicals, ingredients, or raw materials.

This helps maintain consistent product quality and reduces batch failure.

In energy and utilities, monitoring the flow of water, oil, gas, or steam helps operators optimise energy use, detect system inefficiencies, and prevent leaks or losses. Accurate flow rate testing also supports emissions reporting and compliance with environmental regulations.

In building services, flow measurement enables better management of HVAC systems, cooling networks, and fire suppression lines. It supports both sustainability goals and regulatory compliance.

Even in healthcare and life sciences, precise flow rate monitoring is essential, particularly in dosing, sterilisation, and clean-in-place (CIP) procedures.

The versatility of our ultrasonic flow measurement solutions means they can be applied across sectors with equal effectiveness.

Why Choose a Non-Invasive Flow Rate Sensor?

Traditional flow meters often involve complex installation, pipe cutting, and downtime. Our clamp-on ultrasonic sensors remove these barriers.

By attaching sensors externally to the pipe, we eliminate contamination risks, simplify installation, and maintain operational continuity. This makes our systems ideal for retrofitting to existing infrastructure or where fluid purity must not be compromised.

Noninvasive flow meters are also low-maintenance. With no moving parts and no contact with the fluid, there’s little to wear, corrode, or clog. This ensures long-term reliability and a lower total cost of ownership.

Whether you need to measure liquid or gas flow, across metal or plastic pipes, and in both high- and low-pressure systems, our technology offers a flexible, dependable solution.

Who Benefits from Our Flow Measurement Technology?

Accurate flow rate measurement will benefit any organisation that needs to move, monitor, or manage fluids. This includes manufacturers, energy providers, utility operators, engineers, facilities teams, and quality assurance managers.

Our flow meters help you understand how your systems perform, highlight inefficiencies, and reduce the risk of costly process errors. Whether you’re tracking a single pipe or managing a network of flow paths across a facility, our systems scale with your needs.

Our Commitment to Accurate Flow Rate Monitoring

At Coltraco Ultrasonics, we develop technology to help you measure flow with clarity, accuracy, and control, the Permaflow® and Portasonic® 2.FL0 are designed flexibly and precisely, so you can operate more efficiently, comply with regulations, and reduce operating costs.

We’ve worked with customers worldwide to help solve complex flow monitoring challenges, from retrofit projects in live process plants to compliance-led upgrades in sensitive environments.

Read more about how Permaflow® works or visit our case studies to see how we support customers in real scenarios.

Ready to Take Control of Your Flow Measurement?

If you need accurate, non-invasive, real-time flow monitoring for your liquids or gases, we’re here to help. Our ultrasonic flow meters are fast to install, easy to operate, and built to perform.

Please speak to our team today at [email protected] to request product details, book a demonstration, or start your flow rate monitoring project.