Fire suppression systems play a crucial role in safeguarding lives and property from the devastating effects of fires. However, to ensure their effectiveness, it is essential to maintain and monitor the contents of fire cylinders accurately. Ultrasonic level sensor systems have emerged as a reliable and non-invasive solution for measuring the liquid levels inside these cylinders.

Ultrasonic level sensor systems use the principles of ultrasonic technology to measure liquid levels without direct contact. These systems rely on ultrasonic waves transmitted into the fire cylinder, which are then reflected back. By analyzing the returned signals, the sensor can determine if it is in the gas or liquid phase, thereby accurately locating the liquid level.

In pic: CO2 Fire Suppression Cylinders arranged in rows, in a bank.

Importance of Accurate Liquid Level Measurement:

The importance of accurate liquid level measurement in fire cylinders cannot be overstated. Inadequate filling can lead to the inefficiency of fire suppression systems, while overfilling may cause potential hazards during operation. Ultrasonic level sensor systems provide a reliable and non-invasive way to monitor the liquid levels, ensuring that fire cylinders are appropriately filled and always ready for action.

Accurate liquid level measurement is critical for the proper functioning of fire suppression systems. A precisely filled fire cylinder ensures that the system delivers the required agent during a fire incident, effectively suppressing the flames.

Importance of Non-Contact Level Monitoring Technology:

Non-contact level monitoring technology is a game-changer in the maintenance of fire suppression systems. Traditional methods, such as weighing cylinders during installation and servicing or using invasive liquid level “float” devices, can be cumbersome and time-consuming. Non-contact eliminates the need for physical contact and allows for swift and accurate measurements.

Moreover, non-contact level monitoring technology avoids unnecessary disassembly of cylinders, reducing the risk of damage and saving valuable time during maintenance procedures.

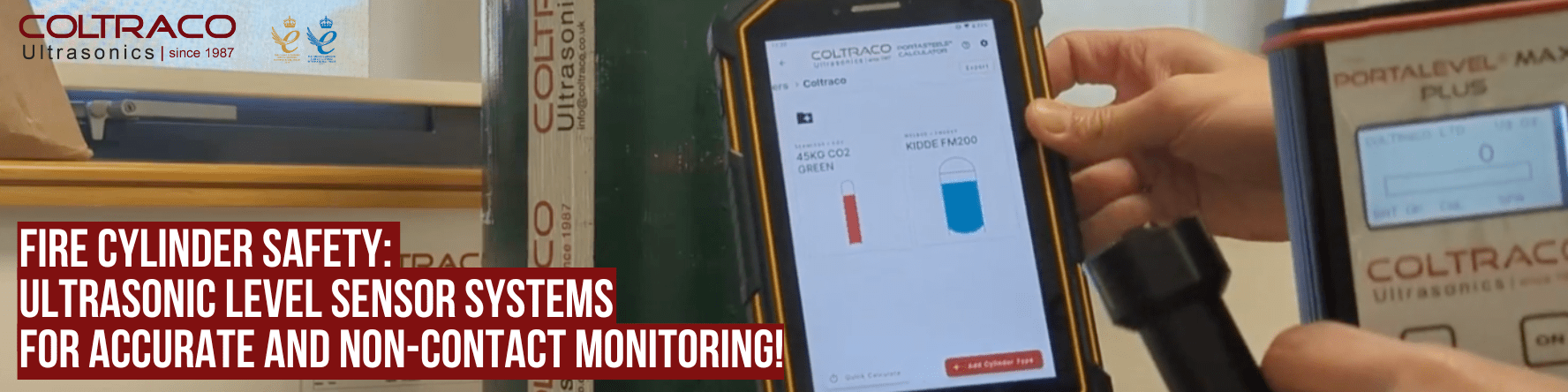

Coltraco Products’ Portalevel® MAX PLUS and Portasteele® CALCULATOR Assistance:

Coltraco Ultrasonics, a leading innovator in ultrasonic technology, offers the Portalevel® MAX PLUS, a cutting-edge liquid level indicator with extended calibration features. This UL-approved device provides unmatched accuracy and versatility, making it ideal for various fire suppression agents like CO2 and Halons.

The Portasteele® CALCULATOR complements the Portalevel® range, providing the world’s first liquid level to agent mass calculator. With this revolutionary tool, users can easily convert liquid levels into agent weights, considering cylinder size, agent type, and temperature. Together, the Portalevel® MAX PLUS and Portasteele® CALCULATOR offer a comprehensive solution for precise liquid level measurement and agent weight determination.

In pic: Portalevel® MAX PLUS

in pic: Portastelle® CALCULATOR

Advantages of Portalevel® MAX PLUS:

- Non-Invasive Liquid Level Measurement: Allows non-invasive liquid level monitoring, eliminating the need for physical contact or invasive float devices during maintenance procedures.

- High Accuracy: With accuracy up to ±1.5 mm, ensuring precise liquid level measurement for improved fire suppression system efficiency.

- User-Friendly Display: The smart and ergonomic design includes a user-friendly display that indicates whether the sensor is in the GAS or LIQUID phase, streamlining the measurement process.

- Versatility: This portable and battery-powered device can test a wide range of fire suppression agents, including CO2, FM200™, NOVEC™ 1230, Halons, FE-13™, FE-25™, NAF S III™, and all core Clean Agent systems.

- Extended Calibration Features: Offers three intelligent calibration modes, providing users with greater control and accuracy when testing various liquids and fire suppression agents.

Advantages of Portasteele® CALCULATOR:

- Agent Weight Calculation: The world’s first liquid level to agent mass calculator. It efficiently converts liquid level measurements from the Portalevel® range into agent weights.

- Time-Saving Solution: By automating the conversion process, streamlining maintenance operations, saving valuable time during cylinder servicing.

- Comprehensive Data: Accounts for cylinder size, agent type, and temperature, providing comprehensive data to ensure the fire cylinder is appropriately filled.

- Minimizes Errors: Manual calculations can lead to inaccuracies, but with the Portasteele® CALCULATOR, the risk of errors is significantly reduced, ensuring reliable and consistent results.

Conclusion

Ultrasonic level sensor systems have revolutionized the way we measure liquid levels in fire cylinders. Accurate liquid level measurement and non-contact level monitoring technology are crucial for the effective operation of fire suppression systems. Coltraco Products’ Portalevel® MAX PLUS and Portasteele® CALCULATOR offer advanced solutions to enhance safety and efficiency in fire cylinder maintenance. With these cutting-edge devices, we can ensure that fire suppression systems are always ready to protect lives and property in the face of potential fire hazards.