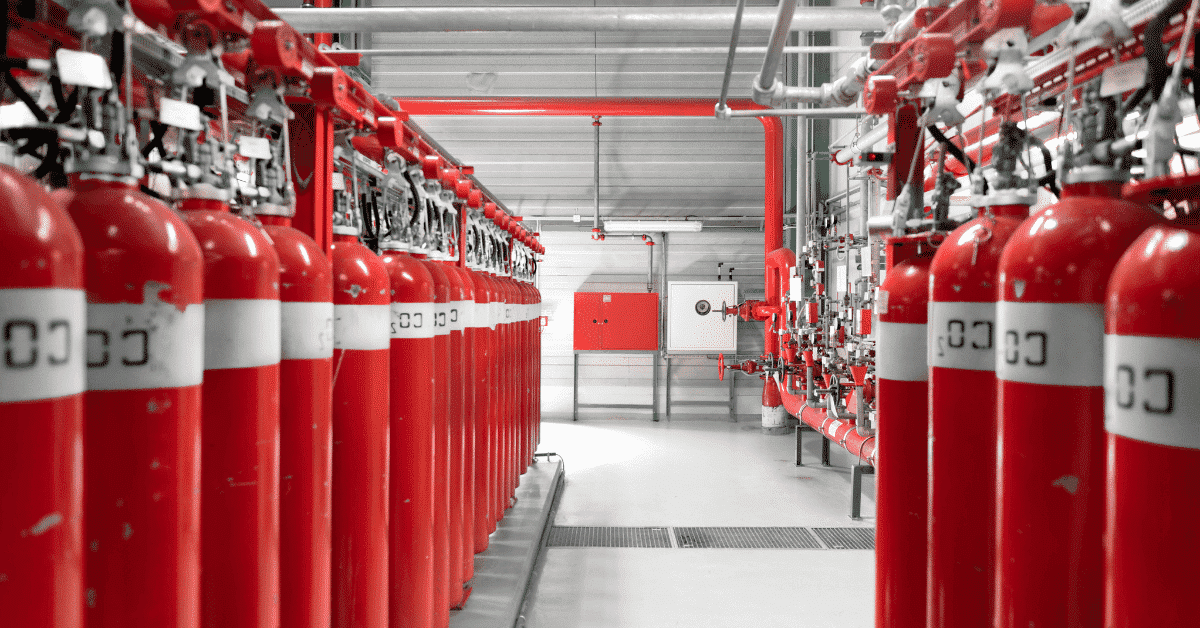

CO2 systems provide an automated response to the outbreak of fire on a ship to ensure that fires are contained and controlled. They do, however, have several limitations; notably that gaseous suppression systems have a required cylinder fill level to ensure operability. Since cylinders are filled to very high pressures in excess of 50 bar, they inevitably experience leakage. Therefore, CO2 fill must be verified in one of several ways to validate a system’s operability. The conventional method of doing this, weighing the cylinders, requires a cylinder to be manoeuvred and usually detached from the manifold in order to detect agent weight. IMO SOLAS FSS Code Chapter 5, 2.1.1.3 states:

‘Means shall be provided for the crew to safely check the quantity of the fire-extinguishing medium in the containers. It shall not be necessary to move the containers completely from their fixing position for this purpose.’

This code specifically states that the crew must test their extinguishing installations in between the periodic inspection, maintenance, and certification. Only having the annual inspection by accredited marine servicing companies is not enough to be best practice and the crew must take responsibility for its own fire protection. However, what must be noted is that the crew are not certified (per IACS Mandate Z17/Rev. 17, Annex 1, Chapter 4.2) to shut down, dismantle, weigh, and re-install the gaseous cylinders and as such cannot be compliant with IMO SOLAS requirements without having means, such as specialist equipment, on board. Agent loss due to leakage can be highly dangerous; if undetected this can seriously impact a system’s operability and ability to combat a fire, since CO2 may not be delivered at the required concentration to properly extinguish a fire.

MSC.1/Circ 1318/Rev.1 outlines the minimum recommended maintenance for fire suppression systems to confirm, at least once every 2 years, that cylinders have at least 90% of the nominal charge. Good practice would dictate that cylinders are assessed more frequently than this since any agent loss could result in the unsuccessful containment of an onboard fire. Gaseous extinguishing systems are highly pressurised and the risk of leaking and discharging is accepted as part of their use, as shown in the regulations that demand their upkeep. The main factor that needs to be understood is that they must be able to actuate, or release their gas, in the event of a fire. The only way to ensure that this is the case is by regular verification of the extinguishing system’s functionality.

However, this is rarely the case since weighing cylinders requires the system to be switched off and will thus not protect the ship for the duration of inspection. Then each cylinder must be removed from the and then be returned and recoupled, which can take 15 minutes. Considering that the average ship may have 600 cylinders, and may only be in port for 4 hours, rigorous inspection of each cylinder requires measurement to be both reliable and time efficient.

Each year, fire is consistently the second leading cause of ship losses worldwide , as shown in Allianz’s Safety and Shipping Review 2023, and so the implications of the failure of a CO2 system are significant. This is where ultrasonic level detection finds its value; by providing a faster, easier way to monitor cylinder fill levels, it not only saves the crew time by streamlining the measurement process, but consequently allows for monitoring to be done more frequently, improving vessel safety. The ability to guarantee, using a measurement process which can be completed in under 30 seconds, an adequate agent level within a fire suppression system, ensures a vessel’s regulatory compliance.

But compliance is only one aspect of the use case; guaranteeing a vessel’s safe operation as a result is far more important. Undetected agent loss from a system can have fatal consequences; detecting this quicker and more easily significantly impacts a vessel’s risk exposure. Additionally, the threat the systems can pose to human life is potentially lethal. Since the agents are designed to deprive fires of oxygen, their inadvertent discharge can asphyxiate humans in their presence. By removing the need to manipulate cylinder manifolds and fittings for agent fill detection, ultrasonic level indication reduces the amount of wear on valves and fittings, and thus the risk of inadvertent discharge.

But compliance is only one aspect of the use case; guaranteeing a vessel’s safe operation as a result is far more important. Undetected agent loss from a system can have fatal consequences; detecting this quicker and more easily significantly impacts a vessel’s risk exposure. Additionally, the threat the systems can pose to human life is potentially lethal. Since the agents are designed to deprive fires of oxygen, their inadvertent discharge can asphyxiate humans in their presence. By removing the need to manipulate cylinder manifolds and fittings for agent fill detection, ultrasonic level indication reduces the amount of wear on valves and fittings, and thus the risk of inadvertent discharge.

There are numerous examples of this occurring; the unintended release of suppressants from fire-extinguishing systems caused 72 deaths and 145 injuries, mainly in the marine industry, between 1975 and 2000. In a 2011 incident at HMNB Faslane, a contractor had to be resuscitated after being exposed to the accidental discharge of a CO2 system while on board the tug SD Nimble. This was a result of human error in the removal of the CO2 cylinders to weigh them. In this instance, the fire suppression system, designed to save lives, operated to threaten or take life.

Examples of this have occurred on larger vessels too; two ro-ro ferries, the Eddystone and the Red Eagle, experienced unintentional CO2 releases from their fire suppression systems in 2016 and 2017 respectively. While no one was harmed in either incident, the presence of dozens of passengers and crew on both vessels meant that a significant threat to human life had been present. Subsequent findings by the MAIB investigation published in 2018 recommended the use of ultrasonic level indication to verify cylinder contents and meet IMO FSS Code, Chapter 5.2.1.1.3, and highlighted the additional benefit of it being able to be easily built into the planned maintenance schedule. This was reiterated by the Maritime & Coastguard Agency’s Safety Bulletin 12 in September 2018.

Ultrasonic monitoring solutions, such as the Portalevel® MAX MARINE PLUS, by removing the need to uninstall and manoeuvre cylinders to weigh them, minimise the risks associated with these procedures by providing a non-invasive measurement process. A cylinder does not need to be detached during the measurement process, meaning the fire suppression system experiences no downtime and continuous fire safety is assured. As shown by examples of accidental discharge, this minimises the risk of loss of life on board a ship.

Consequently, ultrasonic monitoring solutions allow for the safest possible operation of a fire suppression system, guaranteed by a handheld device which requires significantly less manpower and time than other agent verification methods.