Few technologies are as quietly powerful as ultrasonic testing in maintaining safety, efficiency, and compliance across industries.

Whether ensuring room airtightness in data centres, verifying enclosure integrity in power generation, or safeguarding lives at sea, the ability to identify the smallest openings that compromise a system’s tightness is vital to operational safety and reliability.

But how does ultrasonic leak detection actually work, and why has it become such a trusted method across engineering, healthcare, and energy sectors?

In this article, we clarify the science behind ultrasonic technology, explain why Coltraco Ultrasonics’ instruments perform ultrasonic tightness testing, and explore how our innovation in this field has set a new global standard for accuracy and reliability.

Clarifying Leak Detection vs Tightness Testing

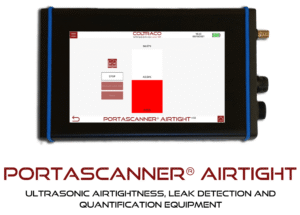

Speaking precisely, the Portascanner® AIRTIGHT does not operate as a conventional ultrasonic leak detector. It performs ultrasonic tightness testing, a proactive process that measures the airtightness or watertightness of an enclosure by detecting where ultrasound can pass through, rather than waiting for leaks to occur.

However, the term “ultrasonic leak detection” is still widely used for discoverability and accessibility. Many engineers and facility managers searching for solutions to identify air leakage use this term, which is why it remains in the title of this article.

In practice, the two are connected: ultrasonic tightness testing identifies exactly where a “leak” would occur by detecting points where ultrasound escapes, allowing users to quantify and improve airtightness.

Coltraco Ultrasonics have refined this technology into the industry-leading Portascanner® AIRTIGHT, enabling engineers to pinpoint even the smallest openings and measure tightness levels with exceptional precision.

Understanding the Science of Ultrasonic Tightness Testing

At its simplest, ultrasound refers to sound waves at frequencies above human hearing, typically above 20 kilohertz. These high-frequency waves are highly directional, allowing them to be used to identify even the smallest transmission paths through solid or sealed materials.

Unlike traditional leak detectors, which rely on sound generated by the turbulence of gas escaping through a leak, Coltraco’s Portascanner® AIRTIGHT operates differently. It uses a controlled ultrasonic generator placed inside the space being tested. This generator emits a continuous ultrasonic signal that fills the enclosure.

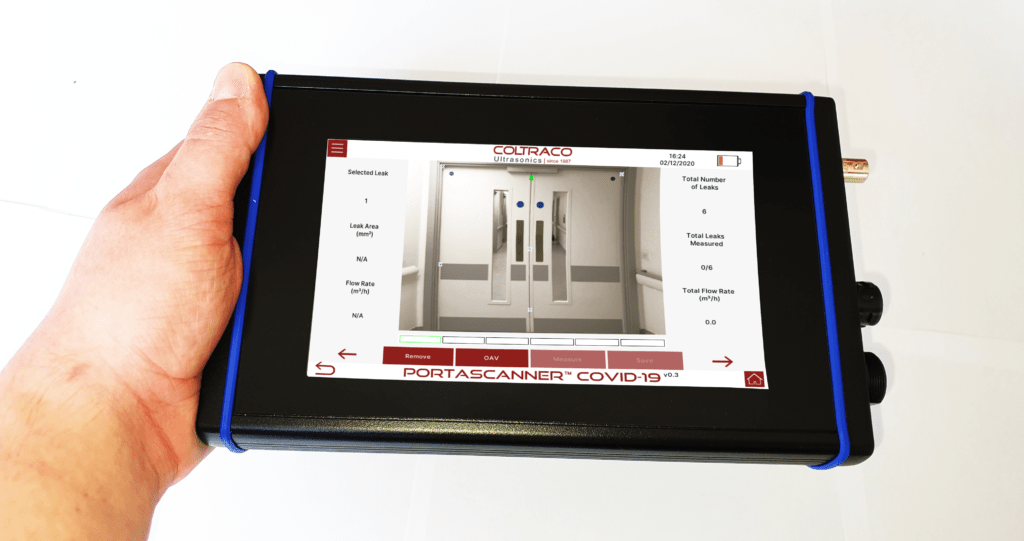

The Portascanner® AIRTIGHT receiver is then used externally to scan along seams, joints, and potential weak points. Wherever ultrasound passes through an opening, even one as small as 0.5 mm, the receiver detects it.

The greater the detected signal strength, the larger or less airtight the gap. In this way, the system identifies and quantifies the precise locations where ultrasound escapes, revealing the tightness and integrity of the structure.

This approach is non-invasive, fast, and quantifiable, providing repeatable results without the need for depressurisation, smoke, or tracer gases.

How Ultrasonic Leak Detection is Performed

Using ultrasonic tightness testing in the field is a straightforward and efficient process.

Position the Generator:

The ultrasonic generator is placed inside the enclosure or room to emit a steady ultrasonic signal.

Scan the External Surfaces:

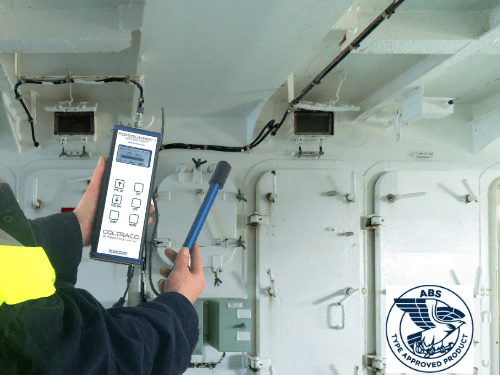

The operator uses the Portascanner® AIRTIGHT handheld receiver to move along seams, door frames, access panels, or ventilation joints.

Detect and Measure:

The receiver measures the strength of ultrasound passing through any openings. Stronger readings indicate larger or less tight gaps.

Record and Analyse:

The instrument’s digital interface allows the operator to visualise, record, and quantify readings to assess overall airtightness performance.

By converting ultrasonic readings into measurable data, engineers can move beyond a simple “pass/fail” result, gaining insight into where improvements are needed and by how much.

Applications Across Industries

Ultrasonic tightness testing supports airtightness assurance in a wide range of environments, including:

Power Generation Facilities: maintaining the integrity of turbine enclosures, control rooms, and ventilation systems.

Data Centres: ensuring sealed spaces to protect cooling efficiency and dust control.

Healthcare and Laboratories: verifying containment and isolation in cleanrooms and biosecure areas.

Marine and Offshore: checking watertight doors, hatches, and compartments for integrity.

Each application benefits from Coltraco’s proven ultrasonic precision, supporting ongoing initiatives in compliance, safety, and energy efficiency.

Advantages Over Traditional Methods

Ultrasonic tightness testing offers a powerful alternative to traditional methods such as pressure decay, smoke, or tracer gas testing.

Non-invasive: No pressurisation or chemicals required.

Rapid and Repeatable: Tests can be performed quickly and frequently.

Quantifiable: Provides measurable data on leak size and airflow rate.

Safe and Clean: Utilises sound, not substances, making it ideal for sensitive environments.

Coltraco’s Portascanner® AIRTIGHT enables precise, data-driven measurement of tightness levels, helping organisations improve environmental performance and ensure compliance with airtightness standards.

Speak To Our Team For Ultrasonic Leak Detection

Ultrasonic tightness testing represents the next generation of integrity assurance, turning inaudible sound into actionable insight.

With the Portascanner® AIRTIGHT, Coltraco Ultrasonics continues to advance the science of non-invasive measurement, providing engineers with the accuracy and confidence needed to safeguard critical environments.

If you would like to learn more about how ultrasonic tightness testing can enhance safety and efficiency in your facility, contact our team today to speak with a Coltraco specialist.