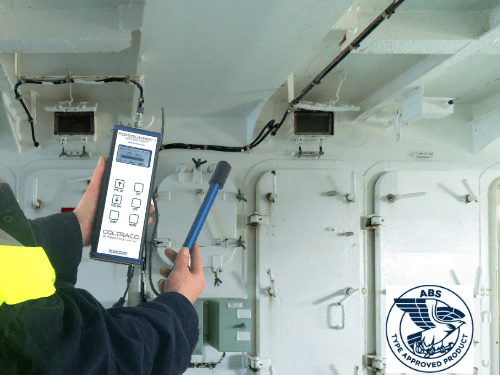

The Portascanner® WATERTIGHT is the world-leading fully ABS Type-Approved & RINA-Accepted watertight integrity tester for inspecting watertight and weathertight seals on ships and marine structures such as warships and offshore oil & gas platforms.

Portascanner® WATERTIGHT is developed to test the integrity of sealed compartments, watertight/weathertight doors, hatch-covers, and multiple cable transit areas with unique dual decibel and linear readings accurate to 0.06mm +/- 0.02mm.

With its unbeaten accuracy and suitability for use by any operator with free training provided and no need for time-consuming, expensive courses, the Portascanner® WATERTIGHT is the easiest way to reliably check for watertightness and weathertightness.

Multiple Cable Transits are designed to act as fire barrier and watertight barrier for cables onboard submarines and across the maritime industry. They are designed so that they must provide fire protection, but also have one or several demands to protect against water, gas and smoke. Cable transits are often the weakest link in the chain of fire safety and water tightness and are key for compartmentation. There have been many accidents and catastrophes caused by sealing systems that didn’t perform when needed. For example, in 2022, HMS Nottingham grounded in Australia during a flooding incident in which secondary flooding occurred above free flooded compartments from water passing through the cable glands and ventilation penetrations. An investigation into the incident concluded that multiple cable penetrations should be examined to ensure that they are sufficiently robust to ensure compartment watertight integrity.

Accordingly IACS have recently mandated Cable Penetration Registers for all Commercial Shipping Rule Sets and for the navies this could present an administrative burden that will also be very onerous to assure. IACS Z28 requires that all Offshore structures must keep a log of all the Multiple Cable Transits in the structure, referred to as a ‘Cable Transit Seal System Register’. This must include information on each cable transit installed, the certification and instruction, drawings and other relevant information from the manufacturer on the Seal itself. This must also include inspection information and any details of any subsequent repair or modification made to the MCT.

Using ultrasonic technology, exact location and severity of any leaks in airtight, gastight or watertight seals can be identified. This is far more efficient compared to high pressure air or water tests, is more accurate and is cheaper.

The most advanced watertight and airtight quantifiers, such as the Portascanner® WATERTIGHT PRO can be stationed onboard, and used as a digital storage and inspection platform, allowing vessels to comply with Z28, ensure compartment integrity, to record and export Cable Penetration/Multiple Cable Transit Area dimensional, quantification and water flow rate data.