VIKING EMEA and Coltraco Ultrasonics partner on a custom ultrasonic liquid level indicator

Coltraco and Viking EMEA are delighted to provide the firefighting market with the first FM approved Non invasive Ultrasonic Liquid Level Indicator

Air Leakage and Tightness Testing

Submit accurate air-tightness testing with Coltraco Ultrasonics to improve energy efficiency, reduce air leakage, and ensure compliance with building regulations. As leaders in ultrasonic technologies, we offer testing solutions that help you detect and eliminate unnecessary energy waste across buildings of all types, nationally and globally.

Effective building design must address air infiltration and air movement to optimize energy performance and reduce environmental impact.

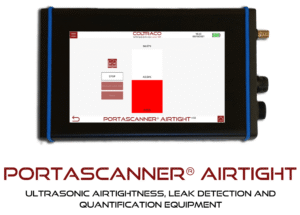

Portascanner® AIRTIGHT is our most advanced ultrasonic room integrity testing tool, contributing to optimal airtightness. Portascanner® AIRTIGHT locates and quantifies even the smallest of leaks and can automatically analyse and consolidate this data, to present these results as indications of a room’s airtightness. This allows for quick testing with extreme precision for applications in the construction, maintenance, or medical fields.

P/N: 509004-AT

CAGE Code: KD983 – COLTRACO LIMITED

The Portascanner® is an ultrasonic room integrity testing tool, allowing you to locate even minor leak sites quickly, easily, and non-destructively. The perfect tool for ensuring and maintaining airtight integrity.

P/N: 509004-520

CAGE Code: KD983 – COLTRACO LIMITED

Air tightness testing measures how much uncontrolled air passes through gaps, cracks or openings in a building. It helps you understand how airtight your building is and where energy loss may occur.

The process identifies areas of air leakage, allowing you to take action to improve insulation, reduce heating and cooling costs, and comply with Building Regulations Part L.

Airtightness testing is key in improving thermal performance and reducing air leakage per hour per square metre of envelope area for both new dwellings and non-dwellings.

Air leakage is one of the biggest causes of energy inefficiency. If warm air escapes or cold air enters through unsealed gaps, your heating or cooling systems work harder, resulting in higher energy bills and increased carbon output.

By completing a proper air leakage test, you’ll:

If you need an air-tightness certificate to ensure compliance, our qualified air testers will deliver accurate results that align with UK regulations.

You need to undergo air-tightness testing at the right stage of construction, usually once the building envelope is complete but before final finishes.

Testing is required for all new builds and developments, especially to meet Building Regulations Part L.

Whether you’re working on smaller buildings or large commercial structures, testing provides the data you need to avoid delays, demonstrate compliance, and identify areas of air leakage before handover.

We offer fast turnaround with same-day reporting where possible, helping you stay on schedule.

Depending on the type and complexity of the building, we apply several industry-approved techniques to conduct air permeability testing. A range of tests, including air permeability tests and air tightness tests, are used to assess building performance and compliance.

This is the most common method of airtightness testing. A large fan is fitted to a main door, and pressure differences are measured to calculate air leakage per hour. It’s ideal for domestic and commercial buildings and provides reliable results in cubic metres per square metre.

Our proprietary ultrasonic method offers a non-invasive solution for detecting air leaks without depressurising the building. It’s especially effective for sensitive or operational environments where conventional methods aren’t suitable.

We use infrared cameras to detect temperature changes caused by air leaks. This method helps visualise areas of concern in the building envelope, such as walls, windows, and ventilation zones.

We offer tracer gas testing to pinpoint micro air leaks for complex structures or critical applications. By monitoring the movement of safe gases through your building, we help identify hard-to-reach or concealed leakage paths.

A typical air-tightness test can take 1 to 2 hours, depending on the building size, layout, and testing method.

Testing may take longer for larger buildings or where air leaks are suspected in multiple zones. Our team provides a complete service, including preparation advice, test execution, and certification on completion.

We also help you prepare for the test, ensuring doors, windows, walls, and ventilation systems are ready to avoid unnecessary delays. Openings such as air bricks should also be sealed during preparation to ensure accurate test results.

Building regulations in the UK require new buildings to meet strict air permeability standards. Air leakage testing helps demonstrate your project meets or exceeds these requirements.

Reducing air leakage can significantly lower a building’s energy consumption, supporting both compliance and sustainability goals.

Whether your goal is regulatory sign-off, improved sustainability, or energy cost reduction, our testing services deliver precise, actionable data.

We understand the needs of modern construction and provide ongoing support throughout your compliance journey, from pre-test preparation to final test reports.

Our air-tightness services are suitable for:

No matter the building type, our qualified air testers ensure every test meets national standards and supports your broader energy efficiency and environmental performance goals.

We combine deep technical expertise with a commitment to service. Our testing methods are accurate, flexible, and suitable for high-rise buildings and smaller premises.

Whether you’re addressing gaps in walls, ventilation pathways, or complex envelope systems, we deliver clarity, confidence, and compliance.

As part of our wider approach to non-invasive diagnostics, our air testing services integrate seamlessly with our broader building performance solutions, ensuring you’re always one step ahead in maintaining an airtight building.

If you want to complete an air-tightness test, ensure compliance with Part L, or reduce energy waste, we’re here to help.

Our experienced air testers work nationwide, delivering clear reports and advice tailored to your building type.

Contact us now to book a test or speak to our team about your air leakage concerns.

Our air leakage detection systems use ultrasound to monitor the airtight integrity of any room or compartment.

Our watertight integrity leak detectors use ultrasound to monitor the watertight integrity of any room or compartment

Acoustic, non-invasive pressure monitoring systems.

Our News

The latest news, technologies, and resources from our team.

Coltraco and Viking EMEA are delighted to provide the firefighting market with the first FM approved Non invasive Ultrasonic Liquid Level Indicator

Coltraco Ultrasonics’ Daniel Dobrowolski accepting the 2025 Wates GFS Sustainable Technology Award. We are proud to announce that Coltraco Ultrasonics has been named a winner

As industries demand ever-higher standards of safety, compliance, and efficiency, it is important to determine which ultrasonic leak detector will lead the market in 2025.