When it comes to fire suppression systems, ensuring the proper functioning of cylinders is of paramount importance. These cylinders are filled with various agents designed to extinguish fires swiftly and effectively. However, if the liquid levels within these cylinders are not accurately maintained, it can lead to disastrous consequences. To address this critical aspect of fire safety, non-destructive liquid level cylinder assessment methods have become indispensable. In this blog post, we will explore the different types of ensuring adequate cylinder performance and types of cylinder liquid level assessment, with a special focus on ultrasonic testing. Additionally, we will discuss how Coltraco Products can assist in this crucial task.

In pic: Two individuals are weighing a cylinder

In pic: An individual is visually inspecting cylinders

Types of Ensuring Adequate Cylinder Performance and Cylinder Liquid Level Assessment

- Visual Inspection: Visual inspection is the most basic form of cylinder assessment. It involves a visual examination of the cylinder’s exterior for signs of damage or leakage. While it’s a fundamental step, it may not provide accurate information about the liquid level inside.

- Weighing Cylinders: Weighing cylinders is a method that involves measuring the weight of the cylinder and subtracting the known tare weight to determine the agent’s weight. This method is relatively accurate but requires emptying the cylinder, which can be impractical in critical applications.

- Pressure Gauges: Pressure gauges can provide some indication of the cylinder’s contents, but they may not be accurate for all types of fire suppression agents and can be affected by temperature and other factors.

Ultrasonic Testing of Cylinder Liquid Level Assessment

Ultrasonic testing is a non-destructive method that has gained popularity for its accuracy and convenience in assessing cylinder liquid levels. It involves using ultrasonic waves to measure the interaction of the ultrasound waves between the sensor and the liquid’s surface inside the cylinder. Here are some advantages of using ultrasonic testing for cylinder liquid level assessment:

Advantages of Ultrasonic Testing:

- High Accuracy: Ultrasonic testing is highly precise as the liquid level is detected based on the ultrasound waves travelling through the medium contained in the cylinder depending on the probe position which can be adjusted with high sensitivity

- Non-Destructive: Ultrasonic testing is a non-destructive inspection method, meaning it does not cause any damage to the object being tested, allowing for thorough examinations without compromising the integrity of the material or structure.

- Real-Time Results: This technique provides real-time feedback, enabling inspectors to make immediate decisions during inspections, which is crucial in industries where safety and quality control are paramount.

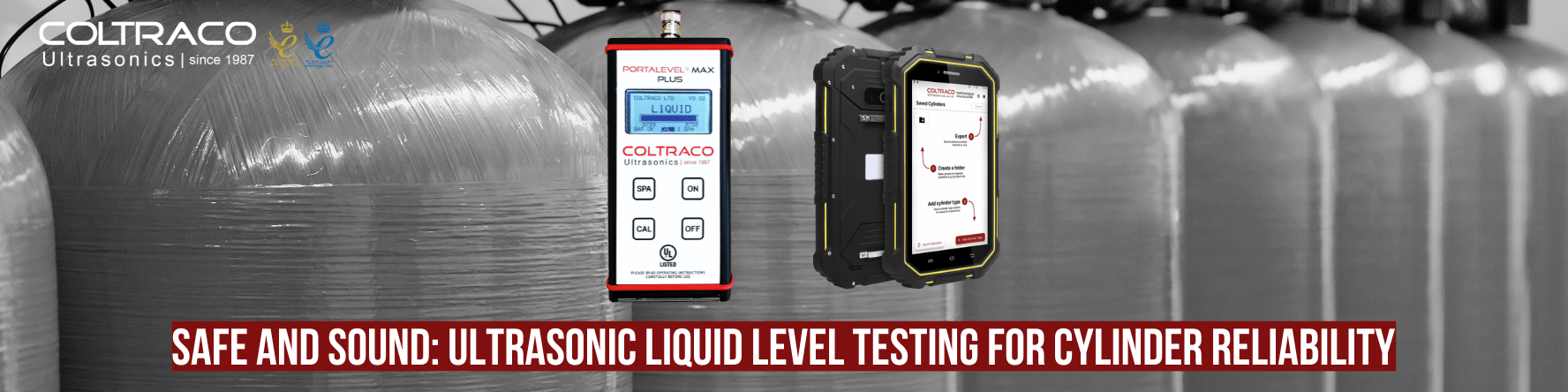

In pic: Portalevel® MAX PLUS

in pic: Portasteele® CALCULATOR

How Coltraco Products Can Assist

Coltraco Products offers advanced solutions for cylinder liquid level assessment, including the Portalevel® MAX PLUS and Portasteele® CALCULATOR. Here are the advantages of these products:

Advantages of Portalevel® MAX PLUS:

- Non-Invasive Liquid Level Measurement: Allows non-invasive liquid level monitoring, eliminating the need for physical contact or invasive float devices during maintenance procedures.

- High Accuracy: Offers accuracy up to ±1.5 mm, ensuring precise liquid level measurement for improved fire suppression system efficiency.

- User-Friendly Display: Features a smart and ergonomic design with a user-friendly display that indicates whether the sensor is in the GAS or LIQUID phase, simplifying the measurement process.

- Versatility: This portable and battery-powered device can test a wide range of fire suppression agents, including CO2, FM200™, NOVEC™ 1230, Halons, FE-13™, FE-25™, NAF S III™, and all core Clean Agent systems.

- Extended Calibration Features: Provides three intelligent calibration modes, offering users greater control and accuracy when testing various liquids and fire suppression agents.

Advantages of Portasteele® CALCULATOR:

- Agent Weight Calculation: Serves as the world’s first liquid level to agent mass calculator, efficiently converting liquid level measurements from the Portalevel® range into agent weights.

- Time-Saving Solution: Automates the conversion process, streamlining maintenance operations and saving valuable time during cylinder servicing.

- Comprehensive Data: Takes into account cylinder size, agent type, and temperature, providing comprehensive data to ensure the fire cylinder is appropriately filled.

- Minimizes Errors: Reduces the risk of inaccuracies associated with manual calculations, ensuring reliable and consistent results.

- Temperature Compensation: Provides precise calculations in varying ambient conditions, enhancing accuracy.

- Easy Integration: Seamlessly integrates with the Portalevel® MAX PLUS for comprehensive testing and monitoring of gaseous suppression systems.

Conclusion

In summary, ensuring adequate cylinder performance is vital for the effectiveness of fire suppression systems. Ultrasonic testing, coupled with advanced products from Coltraco, offers a non-destructive and highly accurate method for cylinder liquid level assessment, ultimately enhancing fire safety and system reliability